Manage your preferences

Cookies are small text files that are used to retrieve information. To ensure privacy, from this panel you can express your preferences for each type of cookie we use.

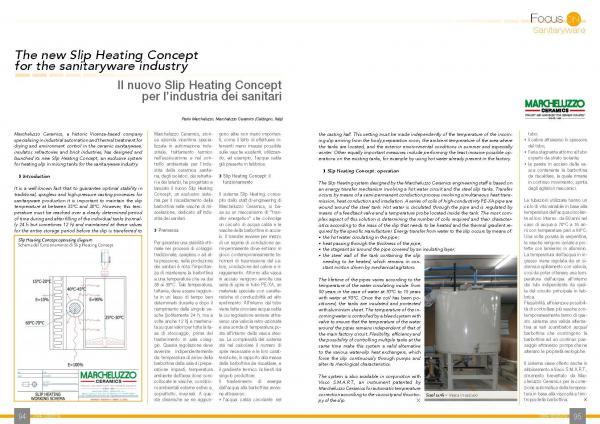

The new Slip Heating Concept for the sanitaryware industry.